HAAS Metallguss GmbH

Industriestr. 19

73347 Mühlhausen im Täle

Services

Further processing and final production

After the parts are cast, customers can choose from the entire spectrum of further processing and final production:

6 presses are available for deburring at HAAS Metallguss GmbH; rough deburring leaves a burr of less than 0.3 mm.

In the case of slide grinding, a bulk process, fine burrs are mechanically removed. The use of various abrasive wheels coordinated with the respective product guarantees that customers get the best possible results.

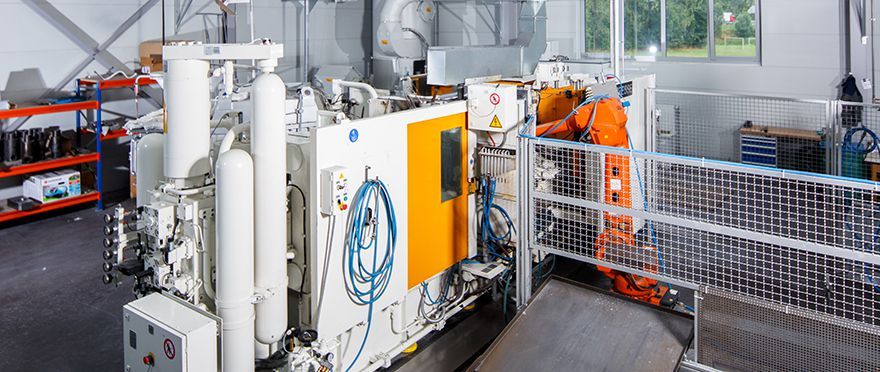

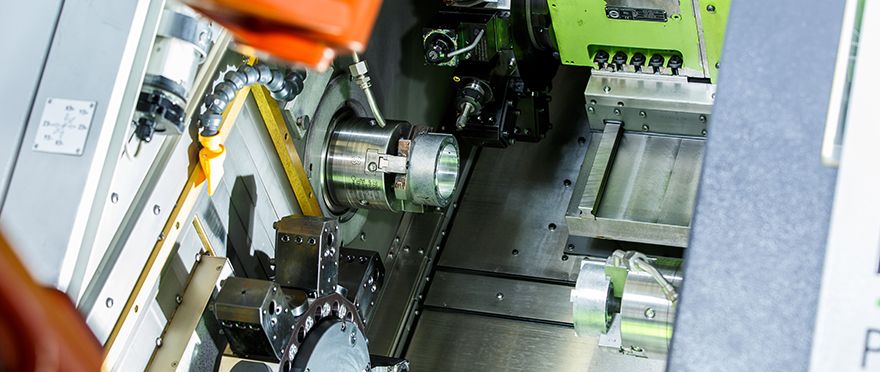

For machining the cast parts, the company falls back on its 13 machining centres, some of which are fully automated. In addition, there are two fully automated lathes with side-operated tools and an NC lathe available for customers.

Critical components are deburred by hand leaving no burr at all. For larger batch quantities, HAAS has fully automated deburring cells.

Of course, HAAS Metallguss GmbH also performs the assembly of ready-to-install components for its customers.

If needed, the company outsources work in the areas of powder coating, painting, cataphoretic painting, ball burnishing, sandblasting, anodizing, etc. to time-tested sub-suppliers.

In-process, component-specific quality inspections are part of the standard production procedure at HAAS.